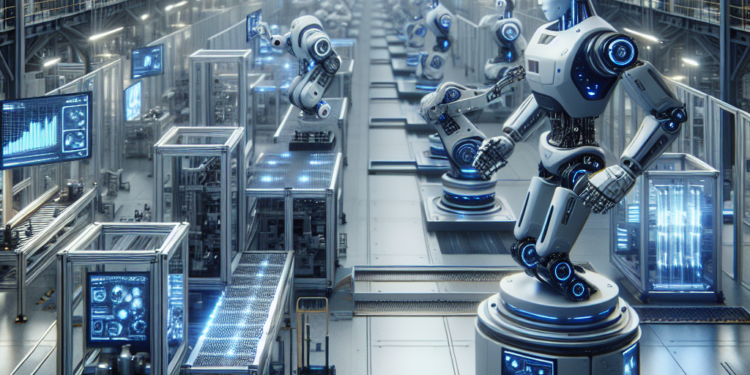

Artificial Intelligence (AI) has been a game-changer in many industries, but perhaps nowhere is its impact more profound than in manufacturing. From assembly to quality control, AI-powered robots are revolutionizing the way goods are produced. These robots are capable of learning and adapting on the fly, making them ideal for the fast-paced world of manufacturing.

One of the key benefits of AI-powered robots in manufacturing is their ability to handle repetitive tasks with precision and efficiency. This means that the robots can take over tasks that are monotonous and potentially dangerous for human workers, freeing them up to focus on more complex and creative aspects of their work. This not only improves the safety of the factory floor but also increases productivity by allowing human workers to focus on higher-value tasks.

AI-powered robots are also highly adaptable, capable of learning new tasks and adjusting their processes in real-time. This means that they can easily switch between different tasks or adjust their approach in response to changing conditions, such as a sudden increase in demand or a shift in production priorities. This flexibility allows manufacturers to quickly adapt to changing market conditions and stay ahead of the competition.

Another key advantage of AI-powered robots is their ability to improve quality control. These robots are equipped with advanced sensors and cameras that allow them to detect defects or anomalies in products with a high degree of accuracy. This means that manufacturers can catch quality issues early in the production process, reducing waste and improving overall product quality.

AI-powered robots are also revolutionizing the way products are designed and manufactured. By analyzing vast amounts of data and simulating different production scenarios, these robots can help engineers optimize the design of products and streamline the manufacturing process. This not only improves the efficiency of production but also allows manufacturers to create more innovative and cost-effective products.

In addition to their technical capabilities, AI-powered robots are also changing the way that manufacturing is organized. These robots can communicate with each other and with other machines in the factory, coordinating their efforts to optimize production processes. This leads to smoother and more efficient workflows, reducing downtime and increasing overall productivity.

One of the key challenges of implementing AI-powered robots in manufacturing is the need for skilled workers who can program and maintain these robots. However, as the technology becomes more widespread, training programs are being developed to educate workers on how to work with AI-powered robots. This not only helps to address the skills gap in the manufacturing industry but also provides workers with new opportunities for career advancement.

Overall, AI-powered robots are revolutionizing the manufacturing industry in many ways. From improving quality control to streamlining production processes, these robots are helping manufacturers to stay competitive in an increasingly globalized and fast-paced market. With their ability to learn and adapt, AI-powered robots are poised to play a key role in the future of manufacturing.